Products & Services

Hydraulic Swing Beam Shearing Machine (NC Optional)

Structure & Design:

- Total Europian design, streamlined look, Monoblock, Welded steel frame with ST44 A1 material.

- Easy for plates to fall down, Accuracy guaranteed.

- High Accuracy, High efficiency, simple and convenient operation, good performance, favorable price and service.

Hydraulic Systems:

- All seals in cylinder is PARKER from USA, the most famous brand good quality and high performance, Hydraulic system is from Bosch Germany.

Hydraulic Press Brake (NC Optional)

Features:

- Totally Europian design, streamlined look, Monoblock, Welded steel frame rigid to deflection moment and high tensile with ST44 A1 Material.

- Adopt integrated hydraulic control system, more reliable and easy for maintenance. Hydraulic system is from Bosch – Rexroth, Germany.

- all scales is cylinder is PARKER from USA, the most famous Brand, good quality and high performance.

- Electrical panel with cooling system designed to meet CE Standarda and composed of automation and electrical equipments with SEIMENS brand.

- The machine by the European Union CE certification and ISO quality system certification.

Hydraulic CNC Press Brake with Delem Controller

CNC Turret Punch

CNC hydraulic turret punch press is a new generation hi-tech punching machine researched and devised by our company technical staff. It adopts hydraulic transmission method, the machine body is integrated welded structure, firm and durable.

Features:

CNC system, ball screw, linear guide, servo system, hydraulic power system, magnetic valve, cylinder, proximity switch, power supply, mould, float clamp, automatic programming.

- it adopts high precision thicken turret which is made by wear-resistant material subtly. Using long-guide mould assures the alignability, which enlarges the mould life.

- It adopts the original CNC system of SIMENS from Germany with standard RS232 interface, language changing between Chinese and English, powerful diagnostic function and universal G-code programming.

- It adopts digital AC servo motor to assure operating speed and running smoothly, long time precision and high reliability. 4) Hydraulic power system is imported from Germany to assure the machine power performance and reliability. Low noise, less heat and energy-saving.

- It adopts standard full float clamp, which is up-down structure to avoid material twisting and transmutation and moved conveniently. It uses brush steel ball compositive worktable. Plate can be processed smoothly and no noise, no scratch.

Laser Cutting Machines

Laser cutting is typically used for industrial cutting of thick materials up to 0.5″. Laser cutting works by directing the output of a high power laser onto the material to be cut.

The material then either melts, burns, vaporizes away, and then is blown away by high pressure air. The addition of the high pressure air leaves an edge with a smooth surface finish. Our CNC laser cutters are used to cut flat-sheet material.

Features:

- No non-recurring engineering fees

- Design complexity has very little effect on the cost of tooling

- Perfect solution for prototype proofing and quick time to market projects

- Designers can tweak a part or try different designs quickly and at low cost

- Prototype parts are produced using the same method as production parts

- Clean and Burr Free Edges

- Does not change the grain structure or hardness of the metal No Stress to metal

Waterjet Cutting Machine

T700 powerful waterjet cutting system is developed for mass production and large sized material cutting. It can expand the cutting speed and material cutting volume with multi-gantry application.

Features:

- Full Nesting(Optimized automatic nesting in accordance with material size)

- Muti-gantry option applicable for T700 to improve cutting speed and productivity

- High performance waterjet system for mass production & large sized material cutting

- High speed/accuracy driving through high precised Helical Rack & pinion driving system

- Improve the system function through optional equipment depends on its cutting environments

- Vertical cutting / ActiveCutting™ / SmartCutting™ / 3D SmartCutting™ / Bevel Cutting head options are all selectable

- Basic Configuration : Cutting table, SJP-6075i pump, Abrasive hopper(1000kg), Smart mini hopper, TopMaster™ waterjet cutting software, Abrasive removal system

- Upgrade : Pump, Cutting head, TopMaster™

- Addable option : Pump, Chiller, Mutiple-axis, Additional Gantry, Height sensor, Drilling unit, Laser edge finder, Closed roop system

Plasma Cutting

High cutting speed with low cost, the speed can increase 2 times compare with oxy-gas cutting.

Features:

- Minimizing, lightness, high quality and energy-saving

- Simple operation with narrow and smooth cutting surface

- Suitable Metal sheet can be cut easily and quickly

- Suitable for cutting stainless steel, copper, iron and aluminum etc

- Auto protection of over-voltage and over-heat

- Be able to work continuously, it can balance automatic when voltage is waving

- Insulated by engineering plastic cover that prevent from electric-shock.

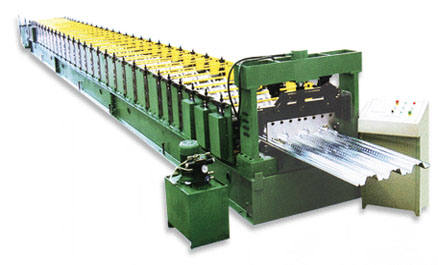

Roll Forming Machines

roll forming machine possesses good features of rational and beautiful structure, stable and reliable performance as well as strong carrying ability. It is mainly composed of 3T hydraulic uncoiler, sheet guiding device, roll forming system, hydraulic cutting equipment, run out table, hydraulic station and PLC controller.

Features:

- roll forming machine, equipped with a computer controlling system, is fairly easy to operate. It can work automatically only through inputting the related production data, such as piece number, length, etc

- If users need to adjust the machine or something else, they must firstly stop the machine before carrying out relevant operations

- Regular lubrication for chain wheel, bearing and speed reducer of Omega roll forming machines should be conducted carefully

- The forming rollers should be kept clean

Iron Worker

Features:

- Q35Y Series Hydraulic Iron Worker, Totally European design,The machine are strong and easy to use machines which are able to can cut and punch all kinds of materials such as plate, square bar, angle, round bar, channel and so on.

- Accurl Industrial hydraulic ironworkers have been designed and built to the highest quality standards in the industry. This profitable machine will serve any grueling fabrication shop for decades to come

- The machine by the European Union CE certification and ISO quality system certification

- Adopt integrated hydraulic control system, more reliable and easy for maintenance.Hydraulic system is from Bosch – Rexroth,Germany.

- All seals in cylinder is PARKER from USA,the most famous brand,good quality and high performance

- Being able to work under rated load continuously,stable working and high precision.

- The rectangular monoblock blades featuring long life with 4 cutting edges, quality high-carbon high-chrome blades D2 quality.

- Electrical components are from European,in accordance with international standards,reliable safety,long life,good anti-interference ability,a radiation unit is fitted in electrical cabinet.

- Protective fence and the safety interlock to ensure the operation safety. Have a movable single-hand pedal switch,easy to operate.

- Emergency stops on machine and foot switch for safety,Foot pedal conforming to CE regulation.